Even for a given application and a given engine different commercial strategies may imply different.

Ceramic thermal barrier coatings for commercial gas turbine engines.

1 5 currently commercial standard tbcs are typically two layered structures consisting of a ceramic.

A tbc system comprises of a substrate bond coat bc and tbc top coat tc.

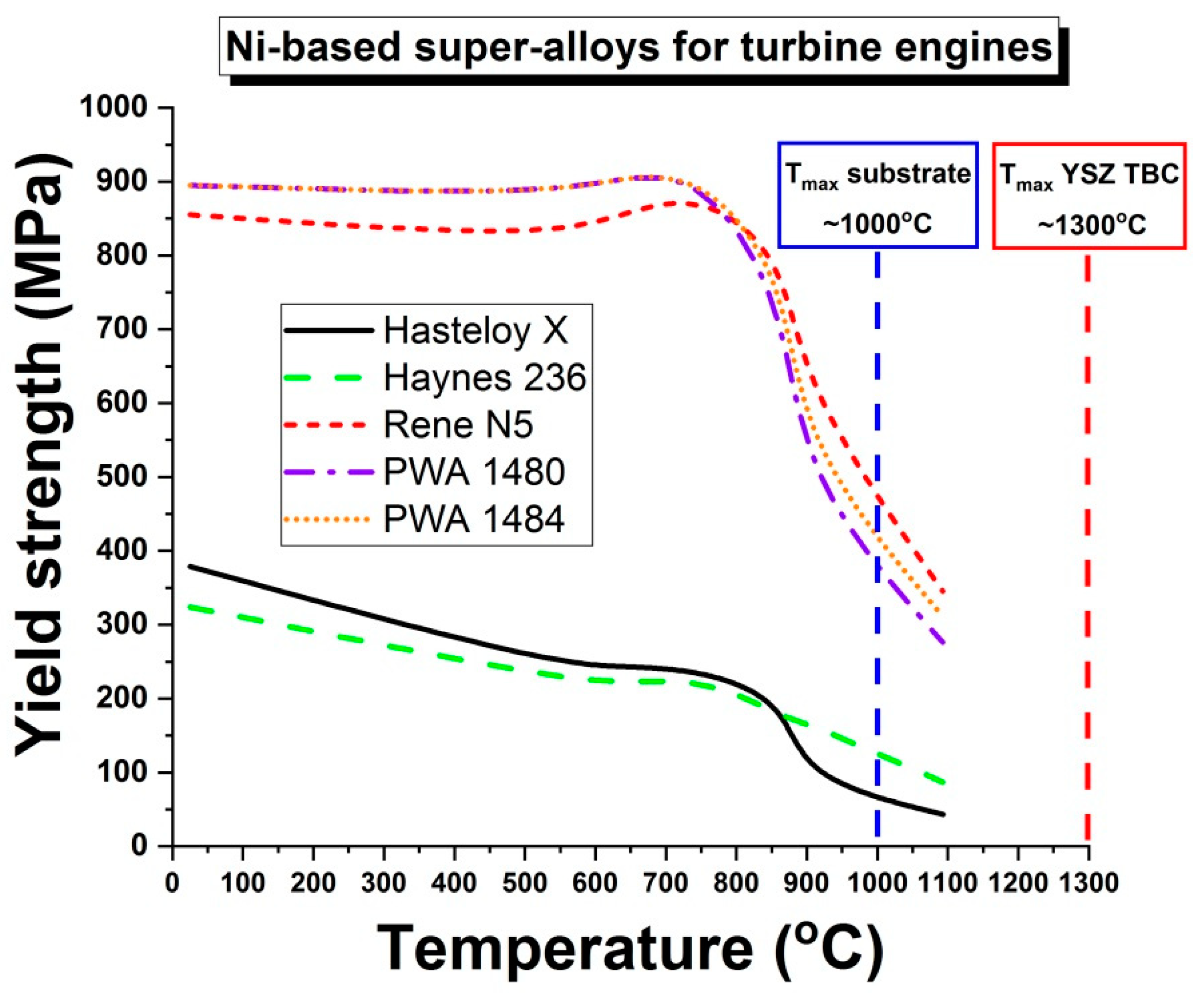

Thermal barrier coatings tbcs are refractory oxide ceramic coatings applied to the surfaces of metallic parts in the hottest part of gas turbine engines figures 1 and 2 enabling mod ern engines to operate at signifi cantly higher gas temperatures than.

And the more development and research that go into thermal barrier coatings the more benefits and higher efficiencies will be the result.

These engines are used in defense sectors energy and transportation applications.

Gas turbine engines and tbc s.

Refractory oxide ceramic coatings or tbc s thermal barrier coatings when applied to.

The most advanced thermal barrier coating tbc systems for aircraft engine and power generation hot section components consist of electron beam physical vapor deposition ebpvd applied yttria stabilized zirconia and platinum modified diffusion aluminide bond coating.

Science 296 2002 280 284 themal barrier coatings for gas turbine engine applications.

Thermal barrier coatings tbcs are widely used in gas turbines to increase the turbine inlet temperature tit or to reduce cooling requirements thus achieving higher engine efficiency lowering emissions and increasing performance goals.

Of all these thermal barrier coatings tbcs have the most complex structure and must operate in the most demanding high temperature environment of aircraft and industrial gas turbine engines.

Thermal barrier coatings have been used for over 20 years to extend the durability of aircraft gas turbine engine combustors.

Thermal barrier coatings tbcs are used to protect the hot sections of gas turbine and jet engines.

Thermally sprayed ceramic and mcraly bond coatings however are still used extensively for combustors and power generation.

Tbcs which comprise metal and ceramic multilayers insulate turbine and combustor engine components from the hot gas stream and improve the durability.

Improvements to the chemical composition of the ceramic and to the composition and microstructure of the underlying bond coat have allowed the application of thermal barrier coating technology to turbine components with similar benefits.