Abstract the thermal conductivity and specific heat of a commercial machinable ceramic have been measured to 0 06 k.

Ceramic thermal conductivity cryogenic.

The lower this value for a material is the lower its thermal conductivity and the better it is at avoiding thermal bridges.

Ceramics especially zirconia based ceramics have been an attractive candidate for fundamental research at cryogenic temperatures due to their favorable mechanical properties corrosion resistance.

The data are compared with those of other materials commonly used in the construction of cryogenic apparatus.

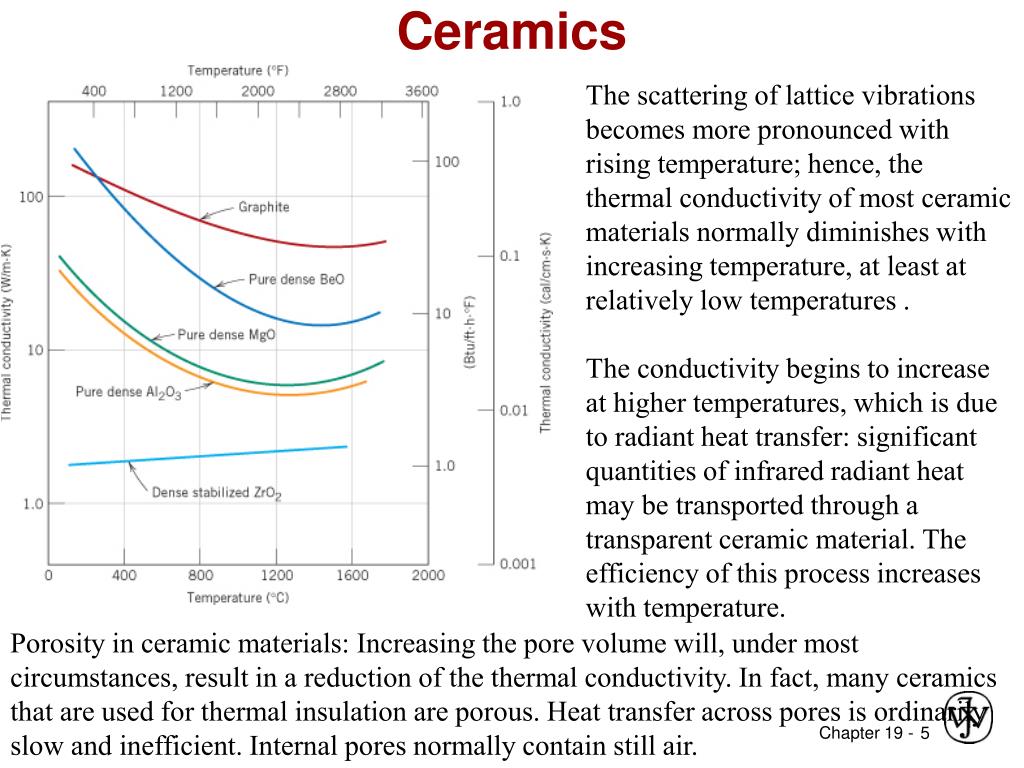

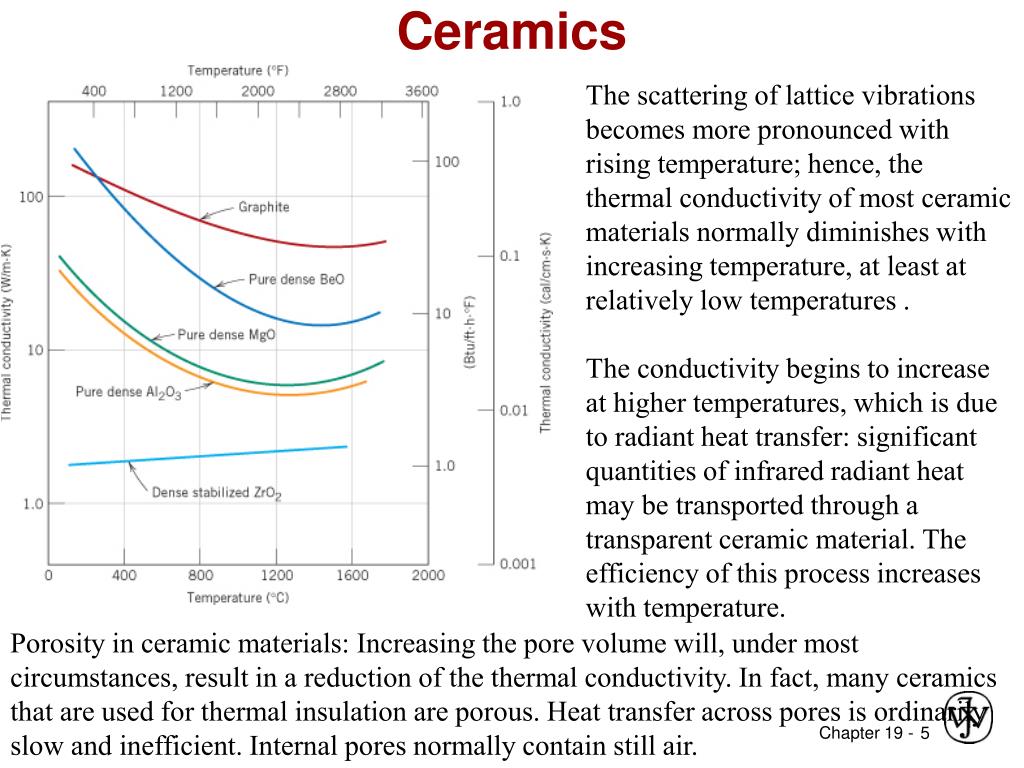

The problem with the thermal conductivity of ceramics is the dependence on the composition grain size and manufacturing process which make it rather difficult to obtain a reliable value from literature only.

The thermal conductivity is specified by the unit of measure w m k.

Since ceramic materials have good mechanical properties and favorable thermal properties low thermal conductivity and thermal expansion they can be used as adequate materials in cryogenic engineering.

The materials currently in the database are ones commonly used in the construction of cryogenic hardware.

The properties available include thermal conductivity specific heat linear thermal expansion thermal expansion coefficient and young s modulus.

The role of impurities and of crystallites is discussed.