The manufacturing process which includes being poured into a mold finished glazed and then sent through a kiln is pretty straightforward and fairly inexpensive.

Ceramic toilet manufacturing process.

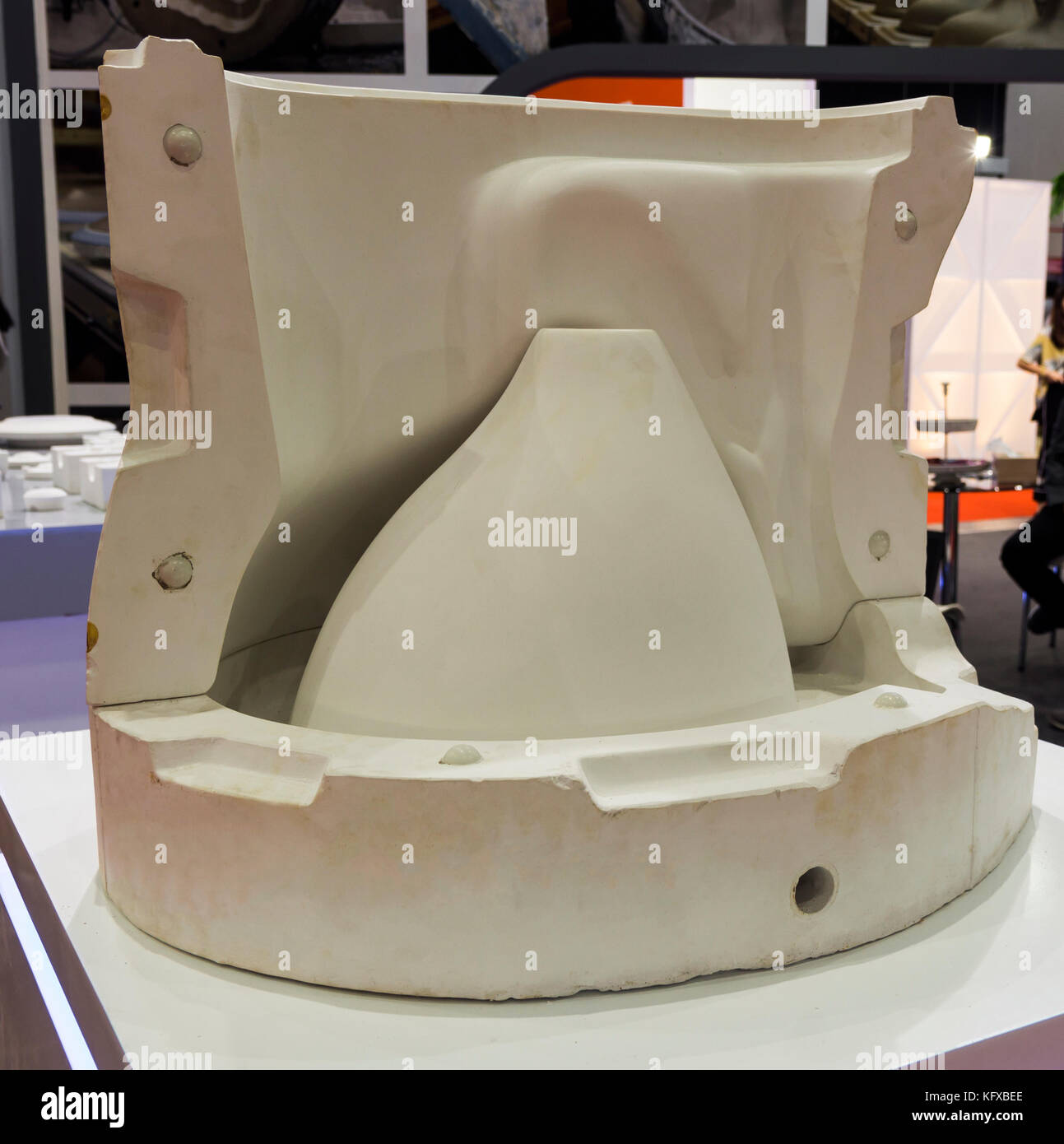

Shaping process dry pressing dry pressing pow deris deposited into a tray and hydraulically pressed bidderand lubricants added keep to the m old 12.

We will see the toilet manufacturing step by step.

The term ceramic forming describes the process of production of ceramic components from natural or synthetic raw materials.

It is also important to add binders or plasticizers as well.

Mixing to obtain a more chemically and physically homogeneous material prior to forming the constituents of the ceramic powder are combined using the method of mixing or blunging.

Get contact details address of companies manufacturing and supplying ceramic toilet ceramic toilet seat across india.

Ceramic tiles are economical to produce because of the raw materials used are easily available mined ceramic minerals.

Video describing the manufacturing process of ceramic tiles realized by ceratec canadian distributor of ceramic tiles porcelain glass mosaic slate and na.

The primary raw material for the tile production is clay quarts and feldspar.

We will discuss all the production process methods used in the ceramic industry.

Most often pug mills are the preferred piece of machinery used in this step of the process when dealing with dry mixes.

There are different production process methods are used in the ceramic production process.

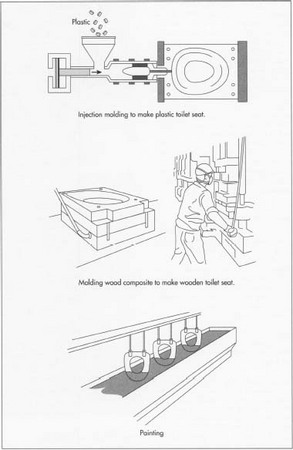

Zinc stearate is a third ingredient in wooden toilet seats.

Batching is the initial step in the tile manufacturing process.

This prevents the wood resin mix from sticking to the mold in the manufacturing process.

This wood flour is blended with a powdered plastic resin called melamine.

Initially a cad diagram is made with the size.

Steps in the tile manufacturing process are.

The wood is hardwood usually maple or birch which has been ground up into the consistency of flour.

Body and glaze preparation.

Glazing process glazing glazing is a layer or coating of a vitreous substance which has been fired to fuse to a ceramic object to color decorate strengthen or waterproof it.

The steps are as follows designing moulding.