The advantages of ceramic over other materials are numerous and although there are some downsides to the use of this material as a whole it is a product which is is extremely compatible with maintaining a clean carefree and safe household and lifestyle.

Ceramics advantages of the jet mill.

How dose a jet mill work.

This article aims to describe the working principle of a jet mill.

The conjet high density bed jet mill is a spiral jet mill combined with a patented dynamic air classifier.

Ball mills can operate in either a wet or dry state.

While milling without any added liquid is commonplace adding water or other liquids can produce the finest particles and provide a ready to use dispersion at the same time.

What advantages does a jet mill have.

Jet mills can be designed to output particles below a certain size while continuing to mill particles above that size resulting in a narrow size distribution of the resulting product.

From general electric to united technologies safran boeing and rolls royce more than 8 000 patents for aerospace design with ceramics have been granted since the early 1980s according to american machinist.

Several of the industry s most sizable players have caught on to the benefits of ceramics in aerospace design too.

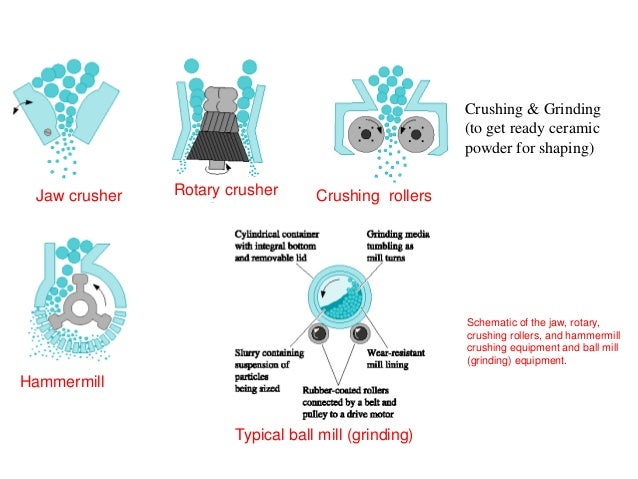

Size reduction is done by impact as the balls drop from near the top of the shell.

Typical operating advantages are.

Applicable for finenesses from 2 5 to 70 µm d97.

A jet mill grinds materials by using a high speed jet of compressed air or inert gas to impact particles into each other.

Ceramic decor items dishes and building materials add unique and personal touches to any home.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering it works on the principle of impact and attrition.

P ulverization takes place in the central chamber of the micron master jet energy mill as the process material is driven at near sonic velocity around the perimeter of the toroidal chamber by multiple jets of air or steam.

Special grinding zone geometry for products free of oversized particles.

No grinding media is involved.

Particles leaving the mill can be separated from the gas stream by cyclonic separation.

Micronization is a term used to describe size reduction where the resulting particle size distribution is less than 10 microns.

A ball mill consists of a hollow cylindrical shell rotating about its axis.

This classifier enables the conjet to achieve highest finenesses independent of the product load and therefore also highest throughput rates.

Alpine spiral jet mills are frequently used in the pharmaceuticals industry and also for the manufacture of fine grade chemicals for ultrafine size reduction of dry materials with a crystalline structure up to a mohs hardness of 3.

A jet mill also called fluid energy mill is used for solid material micronization.

There are no moving parts to.