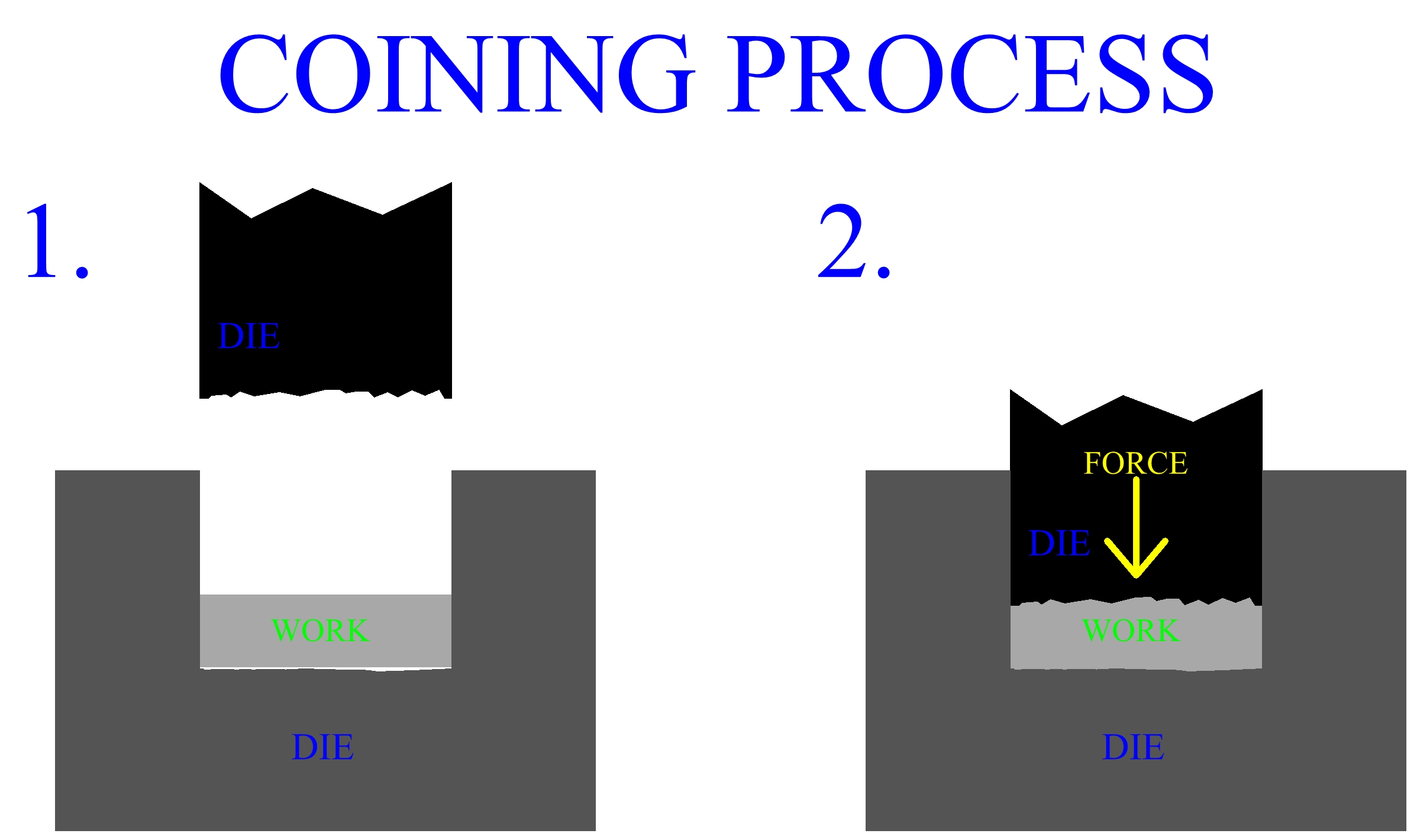

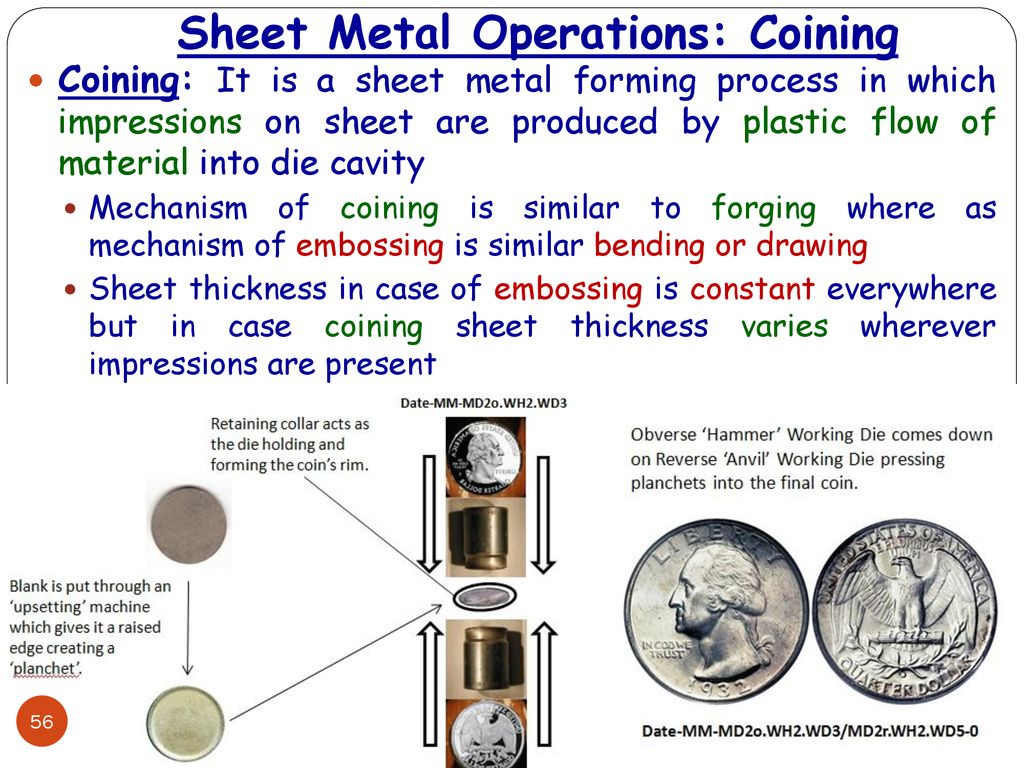

Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material.

Coining sheet metal definition.

How are bending flanging coining embossing stretching curling hemming ironing necking and drawing related.

Metal coining is often a finishing process for manufactured products.

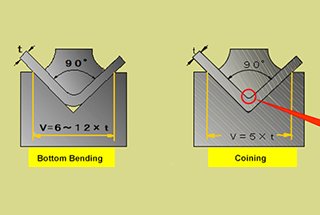

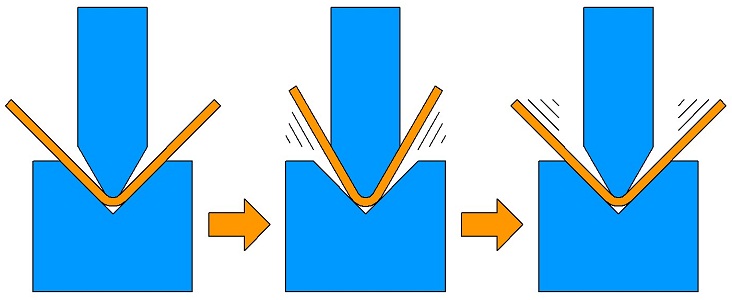

The theory behind coining is that with enough tonnage your sheet metal will bend to the precise angle of your tooling so your tooling should be an equal match to.

In coining the sheet metal is more than just bent it is actually thinned by the impact of the punch and die as it is compressed between them along the bending surfaces fig.

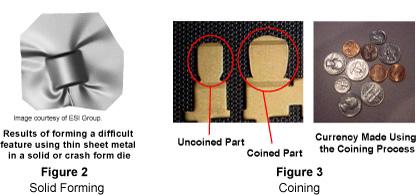

A beneficial feature is that in some metals the plastic flow reduces surface grain size and work hardens the surface while the material deeper in the part retains its toughness and ductility the term comes from the initial use of the.

Stamping includes a variety of sheet metal forming manufacturing processes such as punching using a machine press or stamping press blanking embossing bending flanging and coining.

Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork.

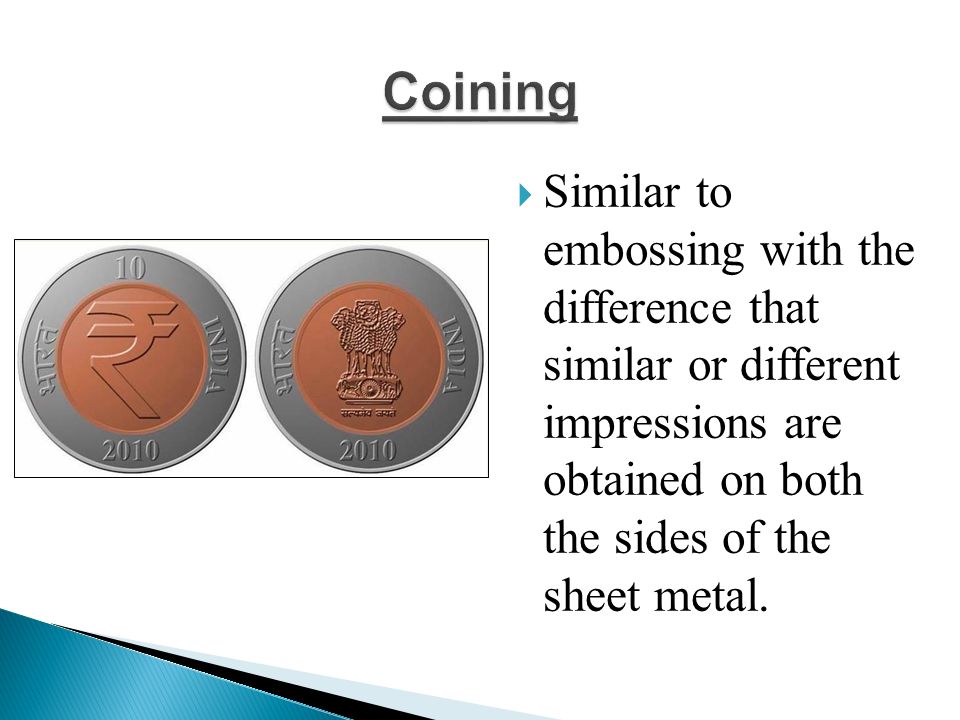

Metal rolling metal extrusion metal drawing sheet metal powder processes metal coining metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece.

For the coining process enough tonnage of the press brake will be used to conform the sheet metal to the exact angle of the punch and die.

Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal.

Find out more about these processes in this final installment of stamping expert art hedrick s sheet metal stamping series.

The term coining is derived from the stamping method of the coin which also means get very high accuracy.

Coining may be used to control surface quality and detail on parts.

This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part or could occur through a series of.